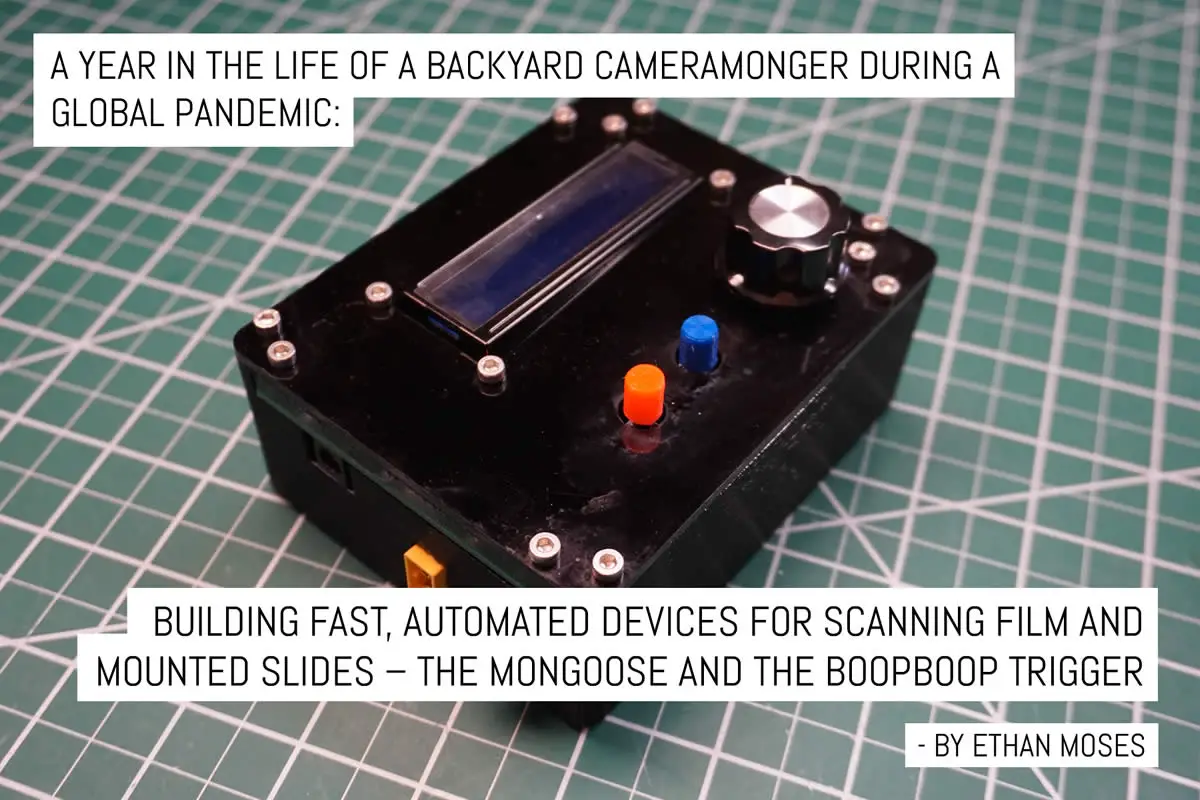

In this article I am going to talk about the journey that led me to build the Mongoose automated negative carrier, and my newest device, the BoopBoop Trigger for digitizing mounted slides. This won’t be so much a technical review or description as much as a meandering memoir for posterity about what I did with my last year.

There are plenty of excellent technical articles and reviews on EMULSIVE, this one will be more of a ‘year in the life of a camera maker during a pandemic’ type of article. At the end, there will be some links and videos that get directly into the BoopBoop, how it works, how to set it up, and how to use it.

Before that, look at something of what I did with 2020:

Today marks the one year anniversary of my being quarantined in my home in New Mexico. Truth be told, I led a quarantined lifestyle to begin with: I live 2,500 miles from the city where I grew up, none of my family lives within 1,500 miles, and most of my friends live elsewhere. I work in my workshop, which is a 40-foot commute from my back door. I have lived on the internet for years now. I quite enjoy it.

This quarantine has been different, though. I’ve had to give up some of my great out-of-the-house pleasures. No eating out, no traveling to see friends and family in person, no street photography, no hanging out at the Makerspace with other obsessive electronics and machining enthusiasts. There has been one major upside to all of this though, which is that as everyone else I know has been quarantined, they have come and met me online and formed communities over the internet. My own personal EMULSIVE.org type of virtual space if you will.

At the beginning of the quarantine, I spent a week or two sitting on the couch watching cartoons and YouTube, not knowing what to do with myself. I thought that if people didn’t go outside, they wouldn’t need as many cameras. My orders choked down to a trickle that first week, and I was unsure that designing new products for the analog film market in a rapidly changing world would be the best use of my time. A friend told me about online groups of engineers building open source pandemic ventilators. American engineers more or less laughed me out of the {chat} room when I suggested building ventilators without computer controls. I build microcontroller systems for work, but I thought that global supply chains grinding to a halt would seriously impede the ability to produce a machine at quantity and scale, also, there were already a ton of open-source designs that used computer logic. I set to building pneumatic valves and pneumatic logic gates as precursor or prototype components to an open-source ventilator in my shop, and open-sourcing them, and making a few YouTube videos about them. I promise, this will have something to do with scanning film, bear with me here.

After a week or two of this, my camera orders had returned. I had gained nothing but an extremely small level of YouTube fame, and I thought that it was about time for me to quit and get back to cameras. The morning I was going to start designing something I got an email from Washington Perez, a designer from Buenos Aires, who was working on a full system with an international group of internet enthusiasts. He said that they had printed my valves in a few countries, and had been using them all in their designs. He asked me to come to their next meeting.

I got pretty choked up when I met Marcos Mendez, a Brazilian photographer who runs a medical equipment repair and servicing company in Sao Paulo, hold up my valves on video chat, and use them with their pump to inflate a latex condom – our earliest test lung. The Brancopan had gone all over the world, but this felt different.

I spent the next two and a half months on a video call once or twice a day, 7 days a week, designing a ventilator with people in Argentina, Brazil, Germany, The Netherlands, and South Africa, that could be made from readily available parts with a minimum of tools. I made lifelong friends in other countries. I learned lessons from them all about materials and components for machines that can be sourced anywhere in the world at quantity, and for not very much money.

I learned to love the humble 608 bearing, ubiquitous in roller skates, skateboards and some 3D printers. I destroyed my rollerblades pulling bearings for prototype machines but managed to leave my skateboard intact. I have no business riding either of them, but the skateboard is a useful dolly for my 200lb centrifuge. Those bearings would later make it into a bunch of photographic machines, and I now buy them by the hundred. We finished our part in this process in late May 2020, with a working prototype that was all open source and free to use for business or pleasure and can be found at openventilator.io. I made a video explaining the system, and then, all of a sudden, it was up to medical testing facilities, labs, manufacturers to pick up the ball and run with it.

I had nothing to do but catch up on camera orders. Soon, I was once again at a loss for what to do with myself.

I have been lucky to call EMULSIVE’s very own EM a friend over the past few years as CAMERADACTYL has grown. He’s been super supportive of the things I make, and a great sounding board about the industry and products that I have worked on. I asked him for some time to help me figure out what to do with myself. We got on the phone on May 6th, 2020. I explained to him that I was pretty exhausted from working on a ventilator for the past three months, and that I did it for free, and now that I had some time ahead of me, I’d like to start working on a photographic project again, but didn’t know which of the 50 or so ideas that I had in my dream camera journal would be profitable, or which people would really love to see on the market.

I pitched him about 10 of my ideas that I had on deck. The clear winner was an automated negative carrier for scanning film with a dslr or mirrorless camera. I more or less live most of my life in a large garage, EM really has his finger on the pulse of the community, and I trust his judgement, and so, I got to work on that one. The next six pages in my notebook from that day’s entry were all sketches and spec lists for a device that would become the Mongoose.

Flipping through my notebook, I had a rough electrical schematic by the 8th of that month, just for an edge detection sensor array, nothing else, no controls, I would have to send commands through a computer. I had built a crude test bed on my 3D printers. If this was a product just for me, I would have stopped here, just a pile of wires and a serial port interface for my computer. Good enough, but not ready to be a real product.

It was June 3rd before I had ‘finished’ the software, which, in retrospect, was not finished at all, but finished enough for when I thought I was ready to redesign a producible housing. On June 17th I made a list of all of the media outlets that I would contact when the thing was done. I had no idea how long it would take before I was ready to tell anyone other than sending EM iPhone video clips of my pile of wires and 3D printed testbed sitting on my desk. On the 19th, I filled an entire notebook page with the thinnest mechanical pencil lines I could make and drew a circuit diagram of the main mongoose circuit board, and all of its accessory boards. I have copied that into at least three other notebooks for reference as I went along.

On the 23rd, I started drawing sketches for PCB layouts and control box housings, and scan modules and some other parts for the final product. On the 24th I designed and sent off a PCB to be printed. I printed out a paper copy and taped it in my notebook. The boards wouldn’t arrive from China until about a week later (with their errors) and required tweaks. This process took almost a month and hundreds and hundreds of dollars in prototypes and international 5-day airmail before I had a set of boards in hand that I was happy with.

In the meantime, I hand wrote a first draft of the instruction manual on the 26th.

In July, I began to design an all laser cut scan module. My first drawing was on the 9th, and I had figured out the interlocking mechanism in a quick sketch at the bottom of the page on the 12th. It was on August 7th when I had a working laser cut prototype and jumped the gun and showed Hamish of 35mmc what I had made. At that point I had a big black acrylic brick of a scan module that worked great, but little did I know that It was virtually un-assemblable.

I went to make 10 units at the laser cutter, got home and threw away a few hundred dollars worth of black acrylic parts, along with my scanner module housing design. I had already promised a bunch of testers and reviewers units, but I knew that this design was going to be murder to actually produce at any scale after assembling just three of them. I went silent for the next three weeks.

On August 23rd, I made the first drawing of the module that would become the production mongoose scan module. It was mostly 3D printed but allowed easier assembly, some extra features, and durability, and eventually, require me to build Albuquerque’s largest print farm to manufacture. I was able to perfect that design and start manufacturing the production prototypes for testers and reviewers by August 27th. That was also the day I started the outline for this article. That was about 7 months ago now. I stopped that and got involved making and shipping a batch of 10 mongooses to testers and reviewers.

The Mongoose Kickstarter went live on September 15th. I sat down again to finish this memoir about the cycle of designing the mongoose on September 20th. I sold a large batch of them on Kickstarter and got involved in ordering parts, printing housings, buying a 1200lb laser cutter for my own shop, sending EMC test units back and forth to a lab, and never got back to the article that I had started months before.

The Kickstarter campaign ended on October 15th: fully funded and then some.

I spent a month going back and forth getting a unit EMC tested with different brands of logically identical components before I could order parts. I blew through more cash on this than anything else in the process. I spent almost two months waiting on parts from China. The same shipping constraints during a global pandemic that led me to work on non-computerized ventilators wound up really slowing me down in filling Mongoose orders.

My 608 bearings however showed up in no time. I have hundreds still. There is one in every mongoose scan module, and six in a project that I have on my desk right now. I bought more printers than I could comfortably fit in my shop. I ordered thousands of dollars worth of plastic filament, and more cans Aqua Net than I had used in my life combined.

For months, my work surfaces were covered in printers, spilling out of the racks that hold the normal print farm. The floor of my shop was covered in large boxes of printed components There was a 6-foot tall stack of about 500lbs of electronics barring my access to the cabinet where I keep prototypes. My mailwoman was exhausted. I was exhausted, but by then I had about $40,000 worth of other people’s money and I felt a crushing need to ship these units to the people who had paid for them. I had stopped all prototyping activities entirely and just assembled all day, every day for months. It was getting pretty miserable in my shop, sanding, and soldering and keeping the printers running with boxes piled high around me.

At some point I bought a ‘long ass wire’ for a fast ethernet connection in my shop, downloaded OBS (Open Broadcaster Software), set up a mirrorless camera as a webcam, and started live streaming as I did the most monotonous of my tasks. I would just sand, solder, or trim parts all day long, hours on end, like demented performance art, sometimes silently, sometimes talking to myself, or playing Mike Gutterman’s Electronic Music For Productions volumes over and over and pretending to be a Top 40 radio DJ. I would open a Google Meet and screen capture it to the top corner of my feed, and leave a link in the video and people could come to talk to me in the world’s most avant-garde entertainment, where I was the one being entertained inside the entertainment.

Those were the best parts of my day for months on end. People came to talk to me from the US and Canada, Argentina, Brazil, Spain, Germany, Romania, England, Wales, and Italy. I am sure that I am forgetting a few. People came to ask about the Mongoose, but also came to talk about photography, 3D printing, laser cutting, and building, designing, and repairing technology of all sorts.

I repaired an air organ over Google Meet. I talked to Alex Purcell about sacrificial anodes in home boiler systems. I had a customer call in about a dry plate holder on a 100-year-old Russian camera while I happened to be chatting with Jason Lane of J. Lane Dry plates and Pictoriographica, designer of lenses for space, and expert in all things optics and photographic. Jason got the customer sorted out pretty quickly and I had one of those moments where I felt something really great had just happened.

I met customers, answered their questions, learned about their photographic interests and practices, learned about their other hobbies. One guest showed me a slideshow and video clips from an indoor RC blimping contest in Munich. I saw electric bicycle and motorcycle designs from Argentina, I walked through building a flat pack pinhole kit that I had shipped to an engineer in Houston. This was probably the best part about the assembly process for me. Getting to meet and talk to interesting people doing interesting things all over the internet, to have them keep my company while I crimped wires for full days on end.

I finally shipped out all of the Mongoose Kickstarter rewards a few weeks ago. The early batches were about a month and a half late, the later batches a bit early, mostly due to the holdup on a few key electrical components. I took a week to catch up on camera and grip orders, go hiking, read a book, do anything else besides soldering. I swept the floor of my shop and consolidated boxes. I sold three 3D printers to reclaim my workbench. Then it was that time again, where I had to decide what project from the dream camera journal comes next. I was hesitant to get into another whole long project that would eat eight months of my time, but also, I cannot help myself and something would wind up intriguing me, taking up pages of my notebooks, hours of my days, a good portion of the dreams that I can remember.

This time I didn’t need to call EM. I was still sore with him over the last good advice that sent me off on this project that took the better part of a year. OK, I wasn’t really mad at all, I just had one of those confluences of interactions that made the next project pretty clear.

One of the first Kickstarter backers had received his mongoose and sent me a thank-you email. He said that he was really enjoying his Mongoose, and wanted me to make a version that would handle mounted slides. This was not the first time that this problem was posed to me. I know that while most people don’t mount slide film for projection anymore, there are still loads of people out there who have maybe 40 years worth of slides shot somewhere between the ’40s and the ’90s that have never been scanned due to the great time cost in scanning a lifetime’s worth of slides.

My uncle Bill has all of my grandfather’s slides from the end of World War II, up until the ’90s when I was a little kid. He was a professional photographer and ran Eastern Studios in Manhattan, and always had a Nikon F or a stereo realist at family events and vacations. I don’t even know how many slides there are, but there are probably a few hundred pounds of them. I also have a family friend Mike, who worked as a photographer from the ’70s and just recently retired. He has a room full of file cabinets filled with Kodak projector carousels filled with slide archives. I knew that there was a market, and Mike had proposed a solution to me, in the form of a request about a year and a half ago, pre-pandemic, which I had in the back of my mind.

Mike had called me one day and told me that since retiring he was trying to downsize some of his enormous gear and archive collection. The kids (my informal cousins) had grown up and left the house, he was retired and just wanted a bit more space. I guess we all probably have dreams of retiring one day and digitizing our entire oeuvres, and maybe that of a loved one, but it’s a slow and tedious task, and there are better things to do than wait on an Epson whirring on for a year of one’s golden years. Mike had pulled the lens off of a slide projector, and pointed his digital nikon with a macro lens down the barrel of the thing, looking at the film gate. He then attached one remote each to the projector and the camera and alternated pressing their triggers to digitize his slides. It worked pretty well, but there were some problems. First, a halogen bulb is HOT and will tend to make the slides move a bit as they expand in the heat, causing an intermittent focusing issue. Second, he had to sit there all day and press one button then the next. Yes, it was faster than an Epson for sure, but it wasn’t fast per se. Mike had asked me to build a cable release that would alternate between triggering a camera and a projector, so he could just walk away from the thing and go about his business until a carousel was finished. I said I thought I could do this for him, but he was in no rush, and we both quickly got on to other projects. At the time, I hadn’t started work on the mongoose, and it was just a one-page sketch in an old notebook. I don’t even remember if I had put the ideas together in my head at the time.

Fast forward to this email from my satisfied Mongoose customer, who wanted a Mongoose that would handle mounted slides just a few weeks ago. A halogen light bulb went off in my head, that I already had a fairly economical and simple solution posed to me last year by Mike sitting on a stool: pressing one button then the next. I wrote back that I would charge maybe $10,000 to figure out how to build a mechanical slide advancing mechanism, but that would be a crazy thing to do, as there are still millions of excellent slide projectors out there that are far better than anything that I could manufacture at my scale these days, and they’re available shipped on ebay for about 80 bucks. Instead, I proposed that the customer buy his own slide projector, and I would build the trigger that alternates between his camera and the projector advance button. He was already using the mongoose to scan film, and so all he would need to do was get a projector and a remote for it. Obviously, a man with enough slides to warrant such a thing already had a projector or two, and was able to find a remote for it on ebay for $15 shipped.

At this point, I didn’t think I had a product. I shoot slides here and there, but I haven’t mounted them for 20 years. I used to scan them on a flatbed with a negative carrier, then later with a Nikon macro bellows, and these days, I just put entire uncut rolls through the mongoose in about a minute. I didn’t know how many people were like Mike, or my uncle Bill, who had massive collections of slides in storage. I offered to make a custom prototype for a half day’s wages for a few days worth of work. I figured I might learn something, and that I would do it at a deep discount. That was still too much, for what it was. The customer counter offered below the cost just in parts of figuring something like this out.

I just couldn’t do that. I took no offense though. I didn’t feel that he was undervaluing my time, we were just valuing different things. I was valuing my time, while he was valuing a product. Often that’s the disconnect that prevents me from making certain things that I would love to work on. So, I made him a deal, I would make no promises and he would make no commitments, but if I decided to make the device a product, I would call him back and see if he wanted one at $300. Deal. I wasn’t sure that this would ever get made at that point.

This was about 2 weeks ago.I put up an instagram post after I got off the call, just text, that said “Market research: Does anyone have lots of mounted slides that they want to scan? Would you be interested in a device that can do 1 frame per 2 seconds @ $300 if you need your own camera and projector? What do you think?”

I almost immediately had a dozen people message me saying they would buy one right now, without knowing even what it was that I wasn’t selling at the time. It was time to build something new. I am never adrift too long between projects.

Within a week I had a working prototype on my desk, Had done much of the heavy lifting and research in designing the Mongoose. I had most of the parts in the dwindling pile of Mongoose components. I had $1000 worth of black filament in stock from a bulk buying spree while I had printers all over the shop. I sent some more custom boards out to China, I ordered some missing parts at retail price from Amazon. I bought a super nice slide projector on eBay before realizing that my uncle Bill had two spares that he would offer me, but I purposely waited to tell him about the project until I was about finished with it.

Yesterday, I finished editing a video about the device which I called the BoopBoop Trigger, which I so named because I am medium bad at branding. I told my Uncle Bill, Mike and my Mongoose customer about it. I uploaded it to YouTube on my 364th day of quarantine. It’s been another interesting year in the workshop.

The trigger works really well. It’s simple and robust and reliable. I’m not ready to jump into another Kickstarter just yet. I’ve been enjoying having at least Sundays off for the last month. I’m also not 100% sure of how many people that such a thing will be useful to. This time around, I think I’m going to sell a batch of prototypes to people who promise to fill out a customer survey and make me an Instagram video of their setup that I might use if I do run a Kickstarter one day.

If you’re interested in a BoopBoop Trigger, you can check out my article on 35mmc about how to build a setup with a camera, a projector, and the BoopBoop, and watch the video above that I made about the project. Send me an email if you’d like to buy one, and are willing to make a video of your setup and send some feedback!

Thanks for reading,

~ Ethan

Share your knowledge, story or project

The transfer of knowledge across the film photography community is the heart of EMULSIVE. You can add your support by contributing your thoughts, work, experiences and ideas to inspire the hundreds of thousands of people who read these pages each month. Check out the submission guide here.

If you like what you’re reading you can also help this passion project by heading over to the EMULSIVE Patreon page and contributing as little as a dollar a month. There’s also print and apparel over at Society 6, currently showcasing over two dozen t-shirt designs and over a dozen unique photographs available for purchase.

One response to “A year in the life of a backyard cameramonger during a global pandemic: Building fast, automated devices for scanning film and mounted slides – the Mongoose and the BoopBoop Trigger”

Fantastic review of an interesting year, and a peek into your workflow. I’m fortunate to have seen some of the behind-the-scenes activities. You rock!